Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and/or follow us on Google News!

Last Updated on: 14th May 2025, 09:16 am

General Motors and The Ford Motor Company are both over the moon about new lithium manganese-rich EV batteries, which GM is pitching as “a leap forward that will offer consumers EVs with an attractive combination of long range and low cost.” Everyone is also waiting for that other well known US-headquartered automaker, Tesla, to join the crushing on LMR EV batteries … waiting….

New LMR EV Batteries Are Coming, Eventually…

Manganese has flitted across the CleanTechnica screen, but don’t confuse it with magnesium. Magnesium is a similarly named but significantly different element, which is also under exploration for use in EV batteries (see more magnesium background here).

Manganese is the fifth most abundant element on Earth, making it a cheap and widely available alternative to other, more expensive battery materials, if only researchers could figure out how to increase the proportion of manganese without crimping performance or lifespan.

On the cost side, one interesting development arose about eight months ago, when a research team based at Lawrence Berkeley National Laboratory in California reported a high level of performance on manganese-based cathodes formulated with large particles.

“Manganese-based materials have tremendous potential to become the next-generation lithium-ion cathode as they are Earth abundant, low cost and stable. Here we show how the mobility of manganese cations can be used to obtain a unique nanosized microstructure in large-particle-sized cathode materials with enhanced electrochemical properties,” the research team reported in the journal Nature.

The use of larger particles — about 1,000 times larger — was a significant split with previous assumptions about the necessary particle size for batteries deploying disordered rock salts (DRX).

“Previous research suggested that to perform well, DRX materials had to be ground down to nanosized particles in an energy-intensive process. But the new study found that manganese-based cathodes can actually excel with particles that are about 1000 times larger than expected,” the researchers noted,

Problem Solved … But Where’s Waldo?

Meanwhile, Ford and GM are not waiting around for the dust to settle. Ford teased a forthcoming LMR battery last month, as widely reported in the automotive media, and GM followed up this week.

If you’re wondering where Tesla is on the topic of LMR EV batteries, that’s no mystery. Tesla CEO Elon Musk famously introduced the idea of high-content manganese batteries five years ago, during his company’s high profile “Battery Day” event.

“At Tesla’s Battery Day 2020, Musk said Tesla’s next generation EV batteries will contain 1/3 manganese,” CleanTechnica reported on September 9 of 2020.

“It’s relatively straightforward to do a cathode that’s 2/3 nickel, 1/3 manganese, which will allow us to make 50% more cell volume with the same amount of nickel,” Musk said during the event.

Whelp, that was five years ago, and where is Elon now? That’s no mystery, either. Last October, Musk was in Washington, DC, meeting with the Governor of Qatar Central Bank and Chairman of Qatar Investment Authority, Sheikh Bandar bin Mohammed bin Saoud Al Thani. “During the meeting, they reviewed the key global financial and investment developments,” reported the English-language Qatar-based news organization The Peninsula on October 22.

The DC meetup happened just two weeks before the results of Election Day 2024 began rolling in, thrusting convicted felon Donald Trump back into the White House with a hefty financial assist from Musk, who returned to Washington a few months later at Trump’s behest in order to dismantle the US government brick by brick.

This week, Musk is visiting the Middle East in person as part of the president’s entourage, and he is reportedly planning to appear at the Qatar Economic Forum 2025 event on May 20 in a live virtual interview.

Coincidentally or not, the government of Qatar has offered President Trump the “gift” of a $400 million luxury jet to replace the official Air Force One official presidential aircraft. Although, security experts note that US taxpayers will be on the hook for many millions more in order to install the necessary equipment.

GM’s Excellent LMR EV Battery Adventure

If you have any thoughts about those goings-on, drop a note in the comment thread. The last we heard, Tesla has patents in the works for LMR EV batteries, but so far no official word regarding production plans has dropped into the publicosphere.

GM, on the other hand, can’t say enough about its new LMR EV batteries, out loud and in public.

“The bottom line: LMR is going to make it possible for GM to offer EVs with premium range at considerably lower cost,” summarized GM’s director of advanced battery cell engineering, Kushal Narayanaswamy, in a GM post on May 13.

“Researchers have been studying LMR technology since the 1990s, attracted by the potential for a new class of electric vehicle batteries offering impressive range and affordable pricing,” Narayanaswamy explained. He also noted that GM’s work on the technology goes back around 10 years with its partner LG Energy Solution. The R&D effort started in 2015 and picked up steam around 2020.

If you’re wondering why GM is looking for the next best thing beyond its NMCA low-mangese EV batteries, that’s a good question. The near-term idea is to deploy prismatic battery architecture to pack more than 400 miles of range into a large SUV or pickup truck, while shaving significant dollars off the cost of the high-nickel NMCA packs.

All else being equal in terms of the total upfront cost of an EV, a pickup like GM’s Chevrolet Silverado EV Work Truck (492 mile range on full charge) will be more affordable to more of the car-buying public when it rides on LMR batteries.

Countdown To 2028 For The EV Batteries Of The Future

The GM/LG collaboration resulted in EV batteries formulated with 35% nickel and 65% manganese. In contrast, a typical high-nickel battery is composed of 85% nickel and just 10% manganese, with cobalt contributing the remaining 5%.

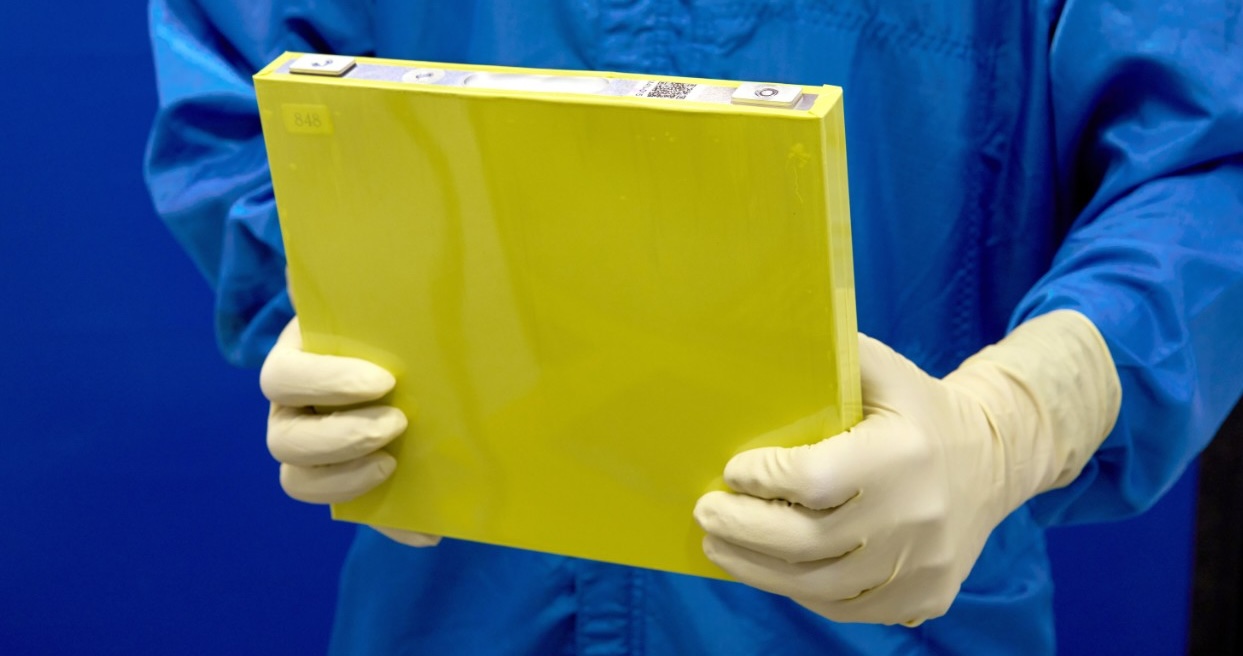

In addition to noting that manganese is more abundant and less expensive than either nickel or cobalt, Narayanaswamy also observes that manganese lends itself to the fabrication of rectangular prismatic cells, which are larger than the pouch-type architecture normally used for nickel cells.

Since LMR EV batteries are larger, they also reduce the amount of connective and structural material that ties the battery pack together, further cutting costs. GM estimates that works out to a cost savings of 75% on battery module components and 50% on total pack components.

“GM estimates that our new LMR cells will get 33% more energy density at a comparable cost than LFP, or lithium iron phosphate, another popular lower-cost EV battery chemistry,” Narayanaswamy also notes.

Hold on to your hats. While Musk is kicking around Qatar, GM CEO Mary Barra has been minding her store. Her company has vowed to be “the first automaker to deploy LMR batteries in EVs,” and that could happen if it beats Ford to the punch.

If all goes according to plan, pre-production will begin in the fall of 2027, with full production to follow in 2028.

Photo (cropped): LMR EV batteries shave costs on materials and other battery components, while performing as well and lasting as long as more expensive high-nickel batteries (courtesy of GM).

Whether you have solar power or not, please complete our latest solar power survey.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy