In-Place Recovery (IPR) offers a transformative approach to mining by extracting minerals through underground leaching, significantly reducing environmental impact, with four parties, including Orica, BHP, the University of Adelaide and Core Resources, looking to leverage this approach and take it forward in a mine site trial,

In 2023, Orica in collaboration with the University of Adelaide, BHP, and Core Resources received a A$2.4M CRC-P Grant from the Australian Government to support an industry-led research endeavour, known as the In-Place Recovery project. The project’s aim is to develop innovative mining techniques that will enable the sustainable extraction of critical minerals while improving safety and reducing energy and water consumption for operators.

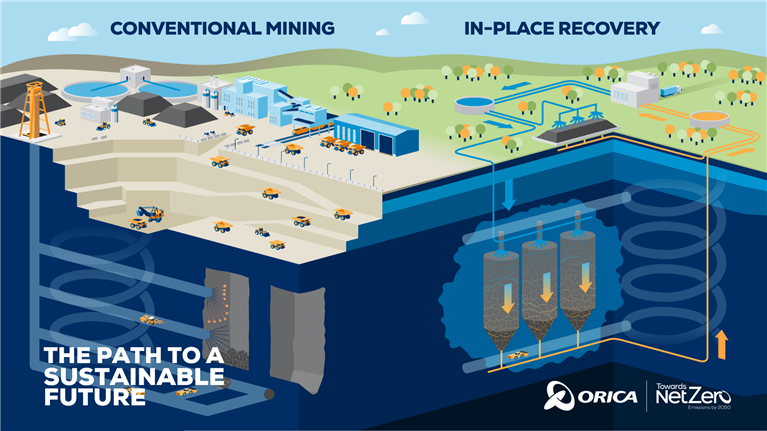

The IPR mining method involves blasting a stope, applying a lixiviant to dissolve metal-bearing minerals and pumping the leach solution to the surface for processing. It’s a safer and energy-efficient alternative to traditional mining, resulting in lower emissions, reduced water consumption, minimal surface disturbance and no tailings, the companies say.

Representative samples were collected from BHP’s Prominent Hill mine in South Australia to conduct the hydrometallurgical test work. The experimental work so far has focused on understanding the mineralogy and leaching behaviour of the ore. Key copper minerals identified include chalcopyrite, chalcocite and bornite.

Initial leaching tests on finely ground rock samples achieved approximately 65% copper extraction within eight hours. These early results are valuable for refining the leaching conditions; however, they should not be interpreted as indicative recoveries through the IPR operation. Future testing using roller bottles and leaching columns will provide a more representative assessment of IPR conditions.

Blast fragmentation modelling has been optimised to improve lixiviant contact by reducing particle size. Adjustment to blast design and explosive energy have decreased the P80 particle size from 178 mm to 69 mm, a significant reduction in contact surface area. In parallel, a comprehensive hydro-thermo-chemical model has been developed to simulate fluid flow, mass transport, chemical reactions across multiple scales, supporting an integrated understanding of the IPR process.

The next step is a small-scale demonstration at the Prominent Hill mine, in South Australia, to test how fluids move through broken rock. This trial will use water and benign tracers to better understand how water flows and is collected underground, and to make sure it stays contained within the stope area.

To ensure environmental safety, the CRC-P team is also carrying out detailed lab experiments and computer modelling. These efforts aim to measure permeability through the surrounding rock under different conditions.

The roles of each party are as follows:

- Orica: Project lead, providing expertise in blasting and extraction, as well as capabilities in fragmentation and stope heave modelling;

- The University of Adelaide: Research partner, experienced in Computational Fluid Dynamic modelling;

- Core Resources: Small to Medium Enterprise partner, conducting metallurgical testing and analysis; and

- BHP: Industry partner, offering site access and strategic support through its Think and Act Differently (TAD) team.

“The IPR project represents a significant leap toward sustainable, efficient and safe mining,” the partners say. “By combining cutting-edge science with industry expertise, IPR has the potential to reshape how minerals are extracted – unlocking low-grade deposits while minimising environmental impact. The upcoming field trials will be pivotal in proving its commercial viability and setting a new standard for the future of mining.”

The post Orica, BHP, Core Resources and Uni of Adelaide progressing In-Place Recovery project appeared first on International Mining.